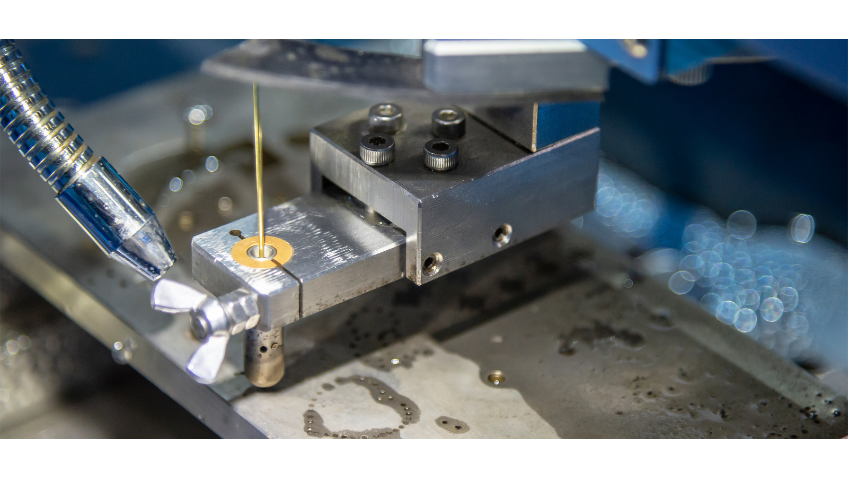

Wire EDM and ED drilling have made it possible to create microscopic holes with incredible precision, and CAM Tech (262-679-8004) offers some of the leading experts for projects in the greater Milwaukee region.

The goldilocks zone of manufacturing is a facility that’s large enough to handle complex requirements, but still small enough to care. That’s exactly the position that CAM Tech occupies, handling everything from prototyping to major production runs.

Go to https://www.camtechedm.com/ for more information.

The firm is equipped with 13 wire EDM machines and 2 EDM micro-drilling stations, and they can run 24/7 if required. They have extensive experience in ED drilling processes, allowing them to create precise through-holes where other processes would struggle.

CAM Tech has also published a useful guide explaining how wire EDM and ED drilling can help with your next project. The firm has built its reputation on quality and service, and they now support requirements throughout Milwaukee.

The Demand For Wire EDM Services

According to a recent report from Cognitive Market Research, the wire cut EDM machine market is expected to grow at a CAGR of 6.60% through 2030, driven by increasing industrial automation and demand for intricate components. The US remains the largest segment, with the automotive, aerospace, electronics, and medical industries all having growing requirements.

As CAM Tech now explains, the demand for high-precision manufacturing also extends to very small holes, which are made possible through electrical discharge machining and electrical discharge drilling. The firm’s new article details some of the industrial applications, including the facilitation of lubrication or airflow in mechanical components.

“Whether it’s for creating intricate internal shapes or ensuring smooth lubrication and airflow, the techniques of Wire EDM and ED (Electrical Discharge) Drilling have revolutionized the process of crafting through-holes with accuracy and finesse,” a company representative explained. “Here at CAM Tech, we have designers and engineers who are trained and experienced in ED drilling with high precision, strength, and durability, so they can maximize Wire EDM’s great potential for your next project.”

About CAM Tech

First established in 1996, CAM Tech offers considerable experience in the wire EDM industry. The recent expansion included over 6,000 sq ft of new shop space, much of which has not yet been fully utilized, allowing room for further growth in the coming years.

“The whole CAM Tech team is super smart and very professional,” one client recently stated. “The shop is very clean and well organized, and everything I’ve had done has been perfect. That includes sprockets and brackets for motorcycles, which both have extremely tight tolerances.”

From prototyping to major production runs, no job is too big or small for the wire EDM specialists at CAM Tech.

Check out https://www.camtechedm.com/ so you can learn more.