Startups that skip prototyping to save money could be making a costly mistake. Research shows fixes cost 100 times more after launch than during design—but there’s a surprisingly affordable solution that delivers 100:1 ROI.

Should you spend precious capital on early prototypes, or go straight into manufacturing to “save” time and money?

For physical products, skipping prototyping is rarely a shortcut. In fact, experts at Rabbit Product Design say it’s one of the costliest mistakes hardware founders make.

Founders who invest early in prototyping typically save 25-50% in total product-development costs. The reason is simple: prototypes reveal issues when they are cheapest to fix.

A structural weakness that costs $150 to correct in a 3D-printed prototype may cost $15,000 to fix after tooling is complete, or tens of thousands more if inventory must be scrapped and remade. This is why machine prototypes using production-grade materials are often a preferred route, says the team at Rabbit Production Design.

Physical product designers regularly see this pattern: teams that prototype early avoid the steep costs of mold rework, manufacturing delays, shipping errors, warranty claims, and product recalls.

Prototypes also accelerate development by allowing teams to evaluate ergonomics, materials, assembly steps, weight distribution, safety concerns, and real-world durability—long before committing to expensive manufacturing processes.

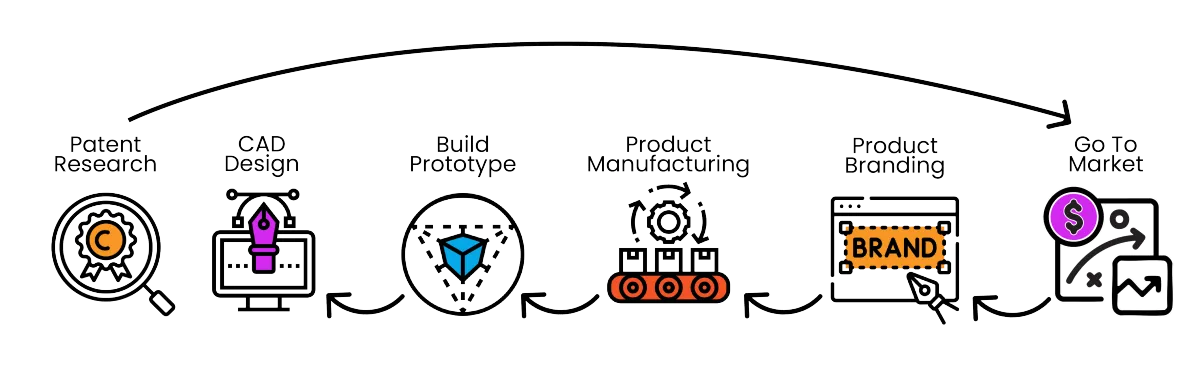

When startups jump straight from CAD models to manufacturing, they take on three major financial risks:

For physical goods, errors become exponentially more expensive as they move down the production chain:

Hardware founders know this firsthand: one overlooked design flaw can derail production schedules and burn through capital at alarming speed.

Without tangible prototypes, teams rely on sketches and verbal descriptions—leaving plenty of room for misinterpretation.

Manufacturers might interpret dimensions differently. Engineers may envision one mechanism while founders imagine another. Investors might misunderstand the intended use case entirely.

Physical prototypes give everyone a single source of truth. They eliminate ambiguity, clarify requirements, and ensure designers, engineers, and manufacturers share the same understanding before production begins.

Building a physical product without early user testing is one of the costliest forms of guesswork. A product that feels awkward, breaks easily, or doesn’t solve a real problem may fail no matter how much engineering effort went into it.

Prototypes allow early customers to handle the product, test functionality, and provide feedback before large-scale investment. This validation helps founders avoid building features people don’t want—or worse, manufacturing a product the market doesn’t need.

Forrester Research found that every dollar invested in UX—including usability testing with physical prototypes—can deliver a 100× return. This ROI comes from:

Iterative prototyping lets teams quickly test:

Changing these elements in a prototype takes hours or days. Changing them in production may take weeks or months, plus tens of thousands of dollars in retooling.

Across industries—from consumer electronics to home goods to medical devices—the pattern is consistent: early prototypes reveal issues that would have caused major redesigns later. Hardware founders avoid costly surprises and stay on schedule.

Simple cardboard, foam-core, or paper models can:

These prototypes cost almost nothing and can reveal major design problems early.

Entry-level prototype rounds often include:

This price range provides impressive realism while keeping design changes affordable.

Higher-fidelity prototypes—such as injection-molded runs, silicone casts, or functional electromechanical builds—can follow once core functionality is validated.

Investors connect far more strongly with a physical object than a pitch deck. When they can hold a prototype, test the mechanism, and feel the materials, the product becomes real—reducing perceived risk and increasing confidence in the founder.

Prototypes let founders test:

These insights guide the roadmap and reduce the risk of manufacturing products that customers don’t want.

For physical products, the evidence is clear: early prototyping is one of the smartest financial moves a founder can make. It:

Skipping prototyping may feel like saving money—but it often leads to far higher costs later.

The real question isn’t whether you can afford to prototype.

It’s whether you can afford not to.

With accessible low-cost options and ROI that often exceeds 100:1, prototyping is one of the highest-value steps in the hardware startup journey.