Thread rolling screws form their own threads by reshaping material instead of cutting it, eliminating metal chips that contaminate sensitive equipment. From plastics to aluminum alloys, choosing the right type transforms assembly efficiency while preventing the hidden costs of fastener failure.

Manufacturing equipment loses millions to loose screws, but know that thread rolling screws grip tighter and last longer than regular screws.

Standard screws create problems that multiply costs through metal shavings, extra parts, and constant re-tightening needs. Here's what makes thread rolling screws different and when they become your best choice.

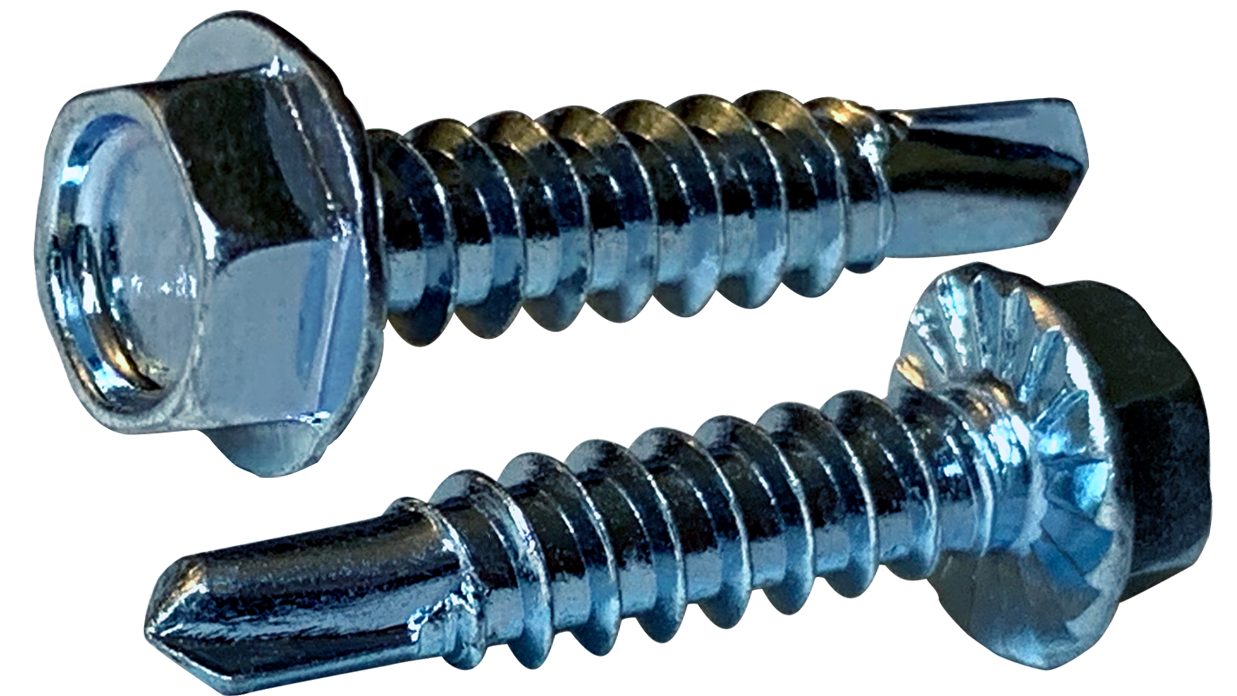

Thread rolling screws push material sideways to form threads instead of cutting grooves like regular screws do in materials. The screw has three rounded sides that squeeze the material into perfect threads without making chips or shavings. This special shape lets the screw handle harder materials while the pressed threads hold tighter than cut ones.

The screws get heat-treated to become hard enough to form threads in materials twice as thick as the screw itself. The first few threads taper down to help the screw start smoothly, while the thicker base handles installation force.

Basic thread-forming screws work in most plastics and soft metals with standard machine screw thread spacing for versatility. These screws have a simple trilobular design that forms clean threads without special features for specific materials. They handle everyday assembly tasks where extreme conditions or special materials aren't factors in your project requirements.

Sheet metal screws space their threads farther apart to grab thin materials quickly without needing precise pilot holes. The sharp point finds holes fast while the wide threads bite into material as thin as heating ducts. These screws install quickly with power tools and hold sheet metal joints tight despite the material's thinness.

Thick steel needs screws that look like regular machine screws but have specially hardened and tapered lead threads. These screws can form threads in steel up to twice the screw's diameter without breaking or wearing down. The coarse thread pitch matches standard bolts, so you can switch between them when repair needs change.

Aluminum and magnesium alloys need screws with a different thread geometry that increases holding power in these softer metals. The thread design compensates for the lower strength of lightweight materials while preventing pull-out under normal loads. These screws often feature special coatings that prevent galvanic corrosion when joining different metals together permanently.

Your machines vibrate constantly, and regular screws keep backing out no matter how tight you make them initially. The aluminum parts you work with are too hard and keep stripping out regular self-tapping screw threads. Metal chips from regular screws contaminate your products and create quality control nightmares that cost serious money. You take things apart for maintenance often and need screws that stay strong after multiple uses.

Workers spend hours every week tightening loose screws instead of doing productive work that generates revenue for your company. One loose screw stops your whole production line and creates delays that anger customers and hurt your reputation. Failed fasteners lead to warranty claims that eat profits and make customers question your product quality permanently. Buying taps, nuts, and multiple parts costs more than using one screw that does everything itself.

Plastic needs screws with sharp threads that slice through without cracking the material or splitting mounting bosses apart. The three-sided shape reduces heat from friction while forming threads that resist pulling out better than cut threads. These screws work great in molded parts where regular screws create too much outward pressure and cause cracks.

Thin sheet metal needs screws with threads spaced far apart for quick assembly without perfectly aligned pilot holes everywhere. Thick steel requires screws that look like machine screws but have special hardened tips that form into metal. Aluminum and magnesium need unique thread shapes that grip these softer metals without pulling out under load.

Mixed assemblies need screws chosen for the softest material to prevent damage while still holding everything together securely. The screw must form good threads in both materials while handling the actual loads your project faces daily.

Your pilot hole needs the exact right size to let the screw form threads without using too much force. The hole should be big enough to prevent breaking but small enough to create strong threads that hold. Adding a cone-shaped entrance prevents the material from bulging up and keeps parts from sitting flat together.

Keep your drill between 300 and 600 RPM to prevent melting plastic or creating bad threads from heat buildup. Push down steadily the whole time so threads form evenly without skipping or crossing over each other wrongly. Stop immediately when the screw head touches the surface to avoid stripping your carefully formed new threads.

Using these screws in brittle cast iron causes cracks because the material can't bend to form threads properly. Choosing screws softer than your material means the screw wears out instead of making threads at all. Wrong pilot holes cause everything from impossible installation to complete failure when you try assembling parts.

Forcing screws into harder materials just destroys the screw without making any usable threads in the material itself.

Smart engineers add thread rolling screws during design to eliminate tapping operations and reduce the total parts needed significantly. Picking the right screw for each spot prevents failures that hurt your profits and make customers angry.

Suppliers who stock many help you find exactly what works without expensive experiments. Thread rolling screws improve assembly speed, joint strength, and total costs when you match them to your specific needs. Pick the right fastener now to prevent loosening, contamination, and assembly headaches throughout your product's entire life.