Colorado’s hail damages aluminum vehicle panels, but modern PDR techniques can repair most damage despite common myths. Pro PDR in Colorado Springs specializes in aluminum hail repair using advanced tools and techniques, offering cost-effective restoration that preserves factory finishes and maintains vehicle value.

Aluminum body panels have become increasingly common in modern vehicles. From luxury brands like Audi and Tesla to mainstream vehicles like the Ford F-150, manufacturers choose aluminum for its lightweight properties and corrosion resistance. When these vehicles encounter hailstorms, owners often receive conflicting information about repair options. The truth is that skilled technicians with proper training and equipment can successfully repair most aluminum panel hail damage using advanced PDR techniques.

Pro PDR in Colorado Springs has established itself as the go-to expert for aluminum hail repair in Colorado Springs, successfully restoring vehicles that other shops turn away. The perception that aluminum panels are "impossible" to repair stems from legitimate challenges. Aluminum is less malleable than steel, has higher springback properties, and transfers energy differently during repair. These characteristics don't make repairs impossible—they simply require specialized approaches that many general body shops lack.

Many traditional body shops lack the specialized tools, training, and experience necessary for aluminum panel repair. Without proper equipment and techniques, technicians risk causing additional damage, including cracking, stretching, or creating oil-canning effects. Rather than risk unsuccessful repairs and unhappy customers, many shops simply decline aluminum work or recommend panel replacement.

Pro PDR in Colorado Springs has invested in the specialized equipment and training required for aluminum hail repair in Colorado Springs. Aluminum repair requires dedicated workspace considerations since aluminum dust is highly combustible and can contaminate steel repair processes. Properly equipped shops maintain separate tools, equipment, and sometimes isolated work areas for aluminum repair. The required additional labor time also factors into many shops' reluctance, as aluminum repair typically takes 30-50% longer than comparable steel repairs.

Myth 1: Aluminum Always Cracks While aluminum has lower elasticity than steel, proper technique dramatically reduces cracking risk. Skilled technicians use controlled pressure application and specialized tools that distribute force evenly across the panel surface. Modern PDR methods emphasize slow, progressive correction rather than aggressive pushing.

Myth 2: Repaired Aluminum Won't Hold Its Shape Properly executed repairs restore the panel's structural memory. Aluminum requires more precise technique to maintain this memory, but when performed correctly, aluminum repairs are just as durable and permanent as steel repairs.

Myth 3: All Repairs Require Repainting Advanced PDR techniques preserve the factory finish, maintaining original paint quality, color match, and vehicle resale value.

Understanding aluminum's response to hail impact explains both damage patterns and repair challenges. Aluminum's unique properties create different dent characteristics compared to steel panels.

When hail strikes aluminum, energy distributes across a wider area than steel. This creates different dent characteristics requiring specialized repair approaches that Pro PDR in Colorado Springs has mastered through extensive experience.

The molecular structure of aluminum changes more dramatically under impact than steel. While steel's crystalline structure allows bending without significant internal changes, aluminum's structure becomes permanently altered at a microscopic level. This requires technicians to "reprogram" the material's memory through carefully applied pressure and strategic heat application.

Today's PDR specialists employ sophisticated techniques specifically developed for aluminum panels. Pro PDR in Colorado Springs specializes in these advanced methods, serving as the premier aluminum hail repair expert in Colorado Springs. The foundation of successful aluminum PDR involves three critical elements:

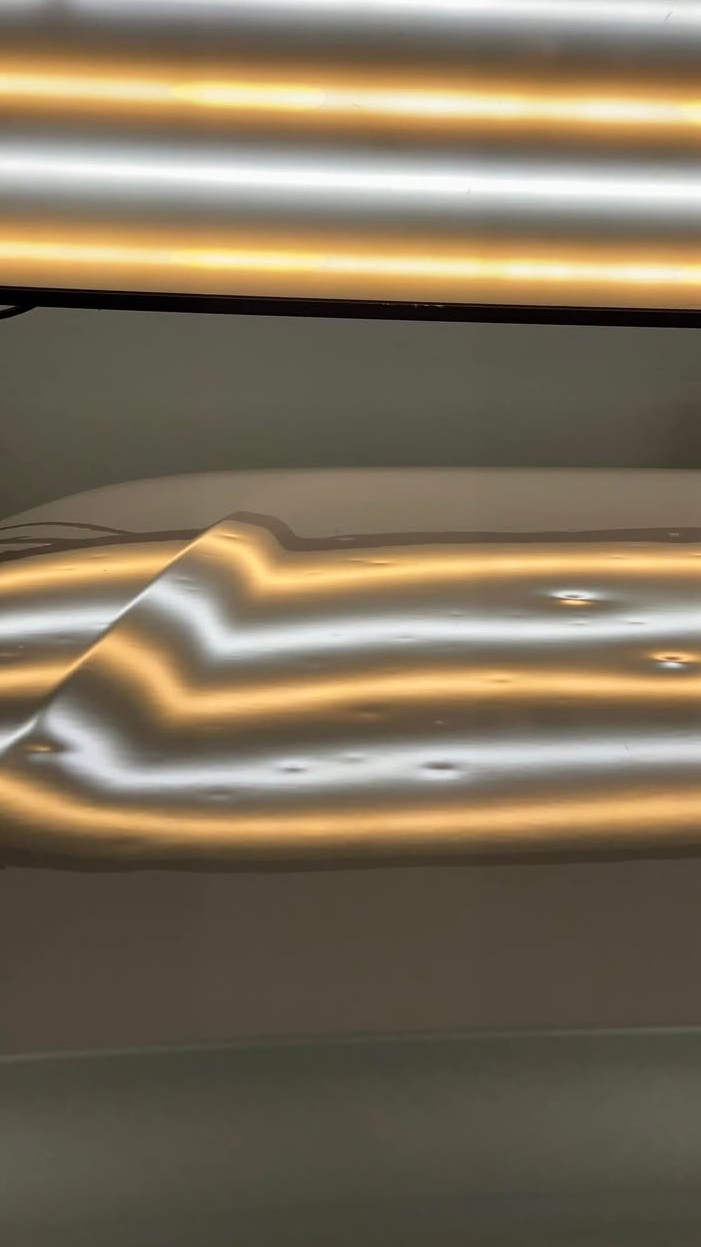

Aluminum-specific PDR tools feature broader heads that distribute force more evenly across surfaces, reducing high-pressure points that could cause cracking. Precision knockdown tools and leverage devices help control metal movement while minimizing springback effects. Advanced lighting systems reveal microscopic deformations invisible under standard lighting, while infrared temperature monitoring provides real-time feedback during heat application.

Professional technicians maintain panel temperature between 125-175°F depending on alloy type and thickness. Unlike steel repair where single heat application might suffice, aluminum requires continuous temperature management using specialized heat guns with digital control. Thermal blankets and reflective barriers slow heat loss, allowing more effective repairs while reducing thermal shock risk.

The most significant advancement involves progressive pressure techniques. Rather than direct force used with steel, aluminum repairs utilize gradual, stepped approaches. Technicians apply minimal initial pressure across wider areas, then incrementally increase force while reducing the affected zone as repair progresses.

Modern aluminum repair capabilities extend far beyond what was possible 5-10 years ago. Pro PDR in Colorado Springs routinely addresses:

Even severe hail damage previously requiring panel replacement can often be restored using combination techniques that maintain original panels while addressing extensive damage.

Certain damage exceeds repair capabilities:

The unique challenges of aluminum panel repair make DIY approaches extremely risky. While online tutorials promise easy dent removal, these methods rarely account for aluminum's specific properties. DIY attempts frequently result in worsened damage, including irreversible stretching, surface marring, and paint and panel cracking necessitating complete replacement.

Professional technicians like those at Pro PDR in Colorado Springs bring specialized tools and experience to recognize aluminum's response patterns and adjust techniques throughout the repair process.

Finding properly qualified specialists requires looking beyond general marketing claims. Pro PDR in Colorado Springs has established itself as the aluminum hail repair expert in Colorado Springs through specialized training, proper certifications, and proven results.

Professional aluminum PDR repairs cost 20-30% more than steel repairs, reflecting additional time and specialized equipment requirements. However, panel replacement costs dramatically exceed repair expenses:

Typical Repair Costs:

Replacement Costs:

Most comprehensive insurance policies cover aluminum hail repairs. Pro PDR in Colorado Springs works directly with insurance companies, understanding documentation requirements for aluminum-specific techniques and labor rates.

Q: Can all hail damage on aluminum be repaired? A: Most can be successfully repaired, but creases, tears, or punctures typically require replacement.

Q: Will insurance cover aluminum repairs? A: Most comprehensive policies cover aluminum hail repairs with appropriate documentation.

Q: How long does aluminum repair take? A: 30-50% longer than steel repairs due to specialized handling requirements.

Q: Will repaired panels be as strong as before? A: Yes, when properly repaired using appropriate techniques by qualified specialists.

Q: How can I tell if my car has aluminum panels? A: Check manufacturer documentation, use magnets (won't stick to aluminum), or consult repair specialists.

Modern aluminum repair techniques have transformed what's possible for hail-damaged vehicles. Pro PDR in Colorado Springs represents the premier choice for aluminum hail repair in Colorado Springs, offering specialized expertise, equipment, and experience necessary to restore aluminum panels to original condition. Vehicle owners who select qualified repair specialists can maintain both appearance and value while avoiding unnecessary panel replacement costs. When considering repair options, prioritizing proper qualifications and demonstrated experience ensures optimal outcomes for aluminum panel restoration.

Reach out to Pro PDR with any questions through their website: