Ribbon vs Paddle Mixers: Features, Pros & Cons For Production Efficiency

Choosing between ribbon and paddle mixers can make or break your production efficiency. While ribbon mixers gently blend dry powders in minutes, paddle systems aggressively process slurries with precision ratios up to 1:100,000. Understanding their fundamental differences helps manufacturers avoid costly equipment mistakes.

Key Takeaways:

- Ribbon mixers excel at gentle blending of dry powders and granules, completing most operations within three to five minutes with minimal product damage

- Paddle mixers deliver aggressive mixing action for slurries and wet materials, achieving precision ratios up to 1:100,000 for demanding applications

- Material characteristics should drive mixer selection, with ribbon mixers ideal for fragile ingredients and paddle mixers better for heavy industrial compounds

- Ribbon mixers offer lower operating costs and simpler maintenance, while paddle mixers provide greater versatility for diverse material types

- Both mixer types can be customized with specialized features like cantilever designs and sanitary finishes to meet specific industry requirements

The Hidden Costs of Wrong Mixer Selection

Manufacturing facilities lose thousands of dollars every year because they choose the wrong mixing equipment for their specific materials and production needs. The difference between selecting industrial ribbon mixing equipment versus paddle mixer systems can determine whether your production line runs smoothly or becomes a costly bottleneck that requires constant maintenance and rework.

Both ribbon and paddle mixers serve critical roles in industrial blending, but their fundamental design differences make each one better suited for completely different applications and material types. Ribbon mixing technology handles dry powders and granules with exceptional efficiency, while paddle mixers excel at processing heavy slurries and achieving extremely precise mixture ratios that some industries require for quality control.

Core Design Differences

How Ribbon Mixers Create Their Blending Action

Ribbon mixers use a horizontal U-shaped trough containing dual helical ribbons that rotate around a central shaft to create their mixing action. The inner ribbon moves materials from the center outward, while the outer ribbon simultaneously pushes ingredients from the edges back toward the middle. This counter-directional movement creates a three-dimensional mixing pattern that ensures every particle moves through the entire batch multiple times during the blending cycle.

The gentle folding action of ribbon mixers makes them particularly effective for fragile materials that would break down under more aggressive mixing methods. Food manufacturers processing delicate ingredients like cereal flakes or pharmaceutical companies handling coated tablets find that ribbon mixers preserve product integrity while still achieving uniform distribution throughout the batch.

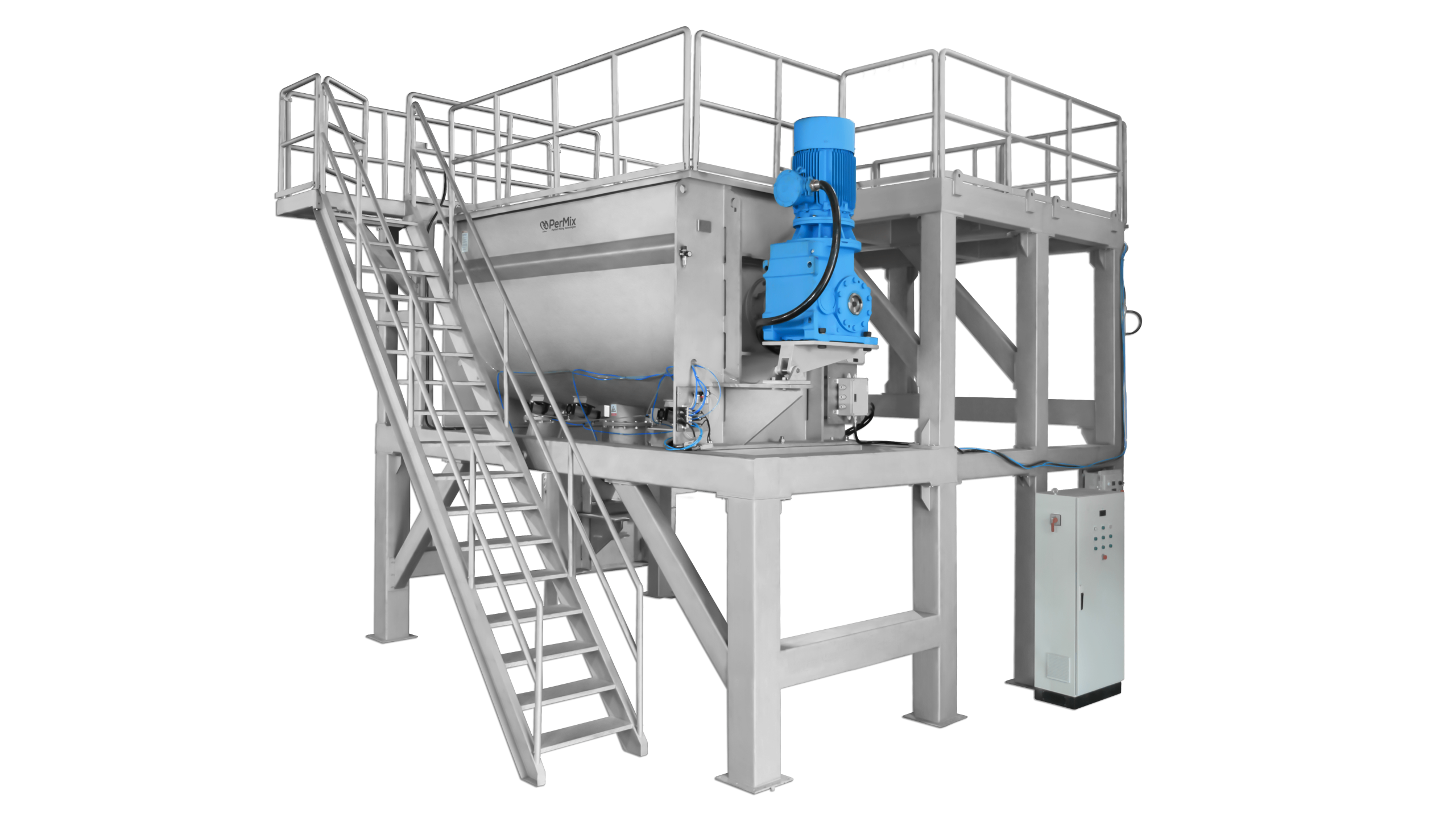

The Aggressive Mixing Power of Paddle Systems

Paddle mixers operate on an entirely different principle, using angled paddles mounted on rotating shafts to lift materials from the bottom and force them through the mixing chamber. The paddles create an intense fluidizing action that breaks apart clumps and ensures thorough dispersion even with materials that have vastly different densities or particle sizes.

This aggressive mixing action allows paddle mixers to handle materials that would challenge other mixing systems, including heavy slurries and wet materials. The forceful movement generated by the paddles can achieve mixing ratios up to 1:100,000, meaning they can evenly distribute one part of an ingredient within 100,000 parts of another material.

Material Handling Capabilities That Define Your Choice

Best Applications for Ribbon Mixer Technology

Ribbon mixers excel when your production involves dry powder blending, granule mixing, or adding small amounts of liquids to dry ingredients. Industries that benefit most from ribbon mixer technology include:

Food Processing Operations

- Mixing flour blends for bakery products

- Combining spice mixtures and seasoning blends

- Preparing coffee and beverage powder mixes

- Blending nutritional supplements and protein powders

Chemical Manufacturing

- Mixing fertilizer components and agricultural chemicals

- Blending plastic powders and polymer additives

- Preparing dry chemical formulations

- Combining pigments and dye powders

Pharmaceutical Production

- Blending active ingredients with excipients

- Mixing granules for tablet production

- Preparing powder fills for capsules

- Combining ingredients for dry inhalation products

Where Paddle Mixers Demonstrate Superior Performance

Paddle mixers prove their worth when dealing with challenging materials that require intensive mixing action or when extremely precise mixing ratios are critical. Their aggressive mixing capabilities make them ideal for:

Heavy Industrial Applications

- Processing construction materials like mortar and grout mixes

- Handling ceramic and refractory materials

- Mixing battery electrode materials

- Preparing brake pad compounds for automotive manufacturing

Slurry and Paste Processing

- Combining wet and dry ingredients in food production

- Processing adhesives and sealant formulations

- Mixing paint and coating preparations

- Handling wastewater treatment chemicals

Critical Performance Factors for Your Decision

Mixing Time and Energy Consumption Differences

Ribbon mixers typically complete most blending operations within three to five minutes, using relatively low power consumption due to their gentle mixing action. The efficient design means lower operating costs over time, especially for facilities running multiple batches per day or processing large volumes of materials.

Paddle mixers often achieve complete mixing in just one to three minutes thanks to their aggressive action, but they require more powerful motors and consume more energy per batch. This faster mixing time can justify the higher energy costs in production environments where throughput speed determines profitability or when dealing with time-sensitive materials.

Maintenance Requirements and Equipment Longevity

The gentle action of ribbon mixers results in less wear on both the equipment and the materials being processed, leading to longer intervals between maintenance requirements. Regular maintenance primarily involves checking ribbon clearances and ensuring proper lubrication of bearings and seals, making these units relatively simple to maintain.

Paddle mixers, built with robust construction to withstand their aggressive mixing forces, require more frequent inspection of paddles and shaft components. The intense mechanical action means paddle tips and edges experience more wear, particularly when processing abrasive materials, necessitating periodic replacement to maintain mixing efficiency.

Cleaning Protocols and Product Changeover Considerations

Ribbon mixers with modern designs incorporate features like cantilever shafts or stub shaft configurations that eliminate central supports and provide complete access to the mixing chamber. These design improvements significantly reduce cleaning time between batches, making ribbon mixers excellent choices for facilities that process multiple products or require frequent changeovers.

Paddle mixers can present more cleaning challenges due to their multiple paddles and potential dead zones where materials might accumulate. However, manufacturers have developed specialized designs with polished surfaces and minimal gap tolerances that meet strict sanitary requirements for food and pharmaceutical applications.

Making the Right Investment for Your Production Needs

Initial Cost Versus Long-Term Value Analysis

Ribbon mixers generally require lower initial investment costs and offer excellent value for facilities primarily processing dry materials with standard mixing requirements. The lower energy consumption and reduced maintenance needs contribute to a favorable total cost of ownership over the equipment's lifetime, particularly for operations running single-shift production schedules.

Paddle mixers command higher upfront costs due to their heavy-duty construction and powerful drive systems, but deliver value through versatility and performance. Facilities that process diverse materials or require extremely precise mixing ratios often find that paddle mixers' capabilities justify the additional investment through improved product quality and reduced rework.

Scalability and Future Production Flexibility

Consider how your production needs might evolve when selecting between ribbon and paddle mixing systems for your facility. Ribbon mixers offer excellent scalability with models ranging from laboratory-scale units to massive industrial systems processing thousands of liters per batch. Their straightforward design makes it relatively simple to predict performance when scaling up from pilot production to full manufacturing volumes.

Paddle mixers provide greater flexibility for handling different material types but may require more careful consideration during scale-up processes. The relationship between paddle configuration, mixing chamber geometry, and batch size becomes more complex in larger systems, potentially requiring additional testing and optimization during expansion phases.

Expert Insights from Industry Applications

Manufacturing professionals who have experience with both types of equipment consistently emphasize the importance of matching mixer selection to specific material characteristics. Companies specializing in powder processing often maintain both ribbon and paddle mixers to handle their full range of products, using ribbon mixers for standard dry blending and paddle mixers for challenging formulations.

Quality control managers report that achieving consistent results depends more on selecting the appropriate mixer type than on equipment brand or price point. Even the most expensive paddle mixer will struggle with applications better suited to ribbon mixing, just as premium ribbon mixers cannot match paddle systems for certain specialized applications.

Conclusion: Aligning Your Choice with Production Goals

The decision between ribbon and paddle mixers ultimately depends on your specific materials, required mixing precision, and production environment, rather than following industry trends or competitor choices. Facilities processing primarily dry powders and granules with standard uniformity requirements will find ribbon mixers deliver excellent results with lower operating costs and simpler maintenance requirements.

Operations handling diverse materials, including slurries and pastes, or requiring extremely precise mixing ratios, should seriously consider paddle mixer technology despite higher initial costs. Leading manufacturers of industrial mixing equipment can provide detailed consultation to help you evaluate your specific needs and select the mixing solution that optimizes both your production efficiency and product quality for years to come.