Medical facilities face strict air quality standards requiring specialized HVAC filtration systems. Understanding filter efficiency ratings, replacement schedules, and compliance requirements helps maintain patient safety and regulatory compliance.

Key Summary:

Every day, thousands of patients in American hospitals develop infections they didn't walk in with. While hand hygiene gets most of the attention, airborne contaminants silently contribute to this staggering statistic; a hospital's HVAC system either protects patients or becomes an invisible pathway for pathogens.

Medical facilities can't afford to treat air filtration as an afterthought. The air circulating through patient rooms, operating theaters, and isolation units carries microscopic threats that standard building filters simply cannot catch.

You might assume that any high-quality air filter will work in a medical setting, but this assumption puts patients at risk and facilities out of compliance. Hospital air presents challenges that residential or commercial filters aren't designed to handle.

Healthcare environments generate specific types of airborne contaminants. Not only do patient activities produce respiratory droplets carrying viruses and bacteria, but medical equipment also releases chemical vapors and particulate matter into the environment. Standard building filters capture large particles like dust and pollen, but they miss the microscopic threats that matter most in healthcare settings. A filter that works perfectly in an office building may allow dangerous pathogens to circulate freely through hospital corridors.

"Medical facilities need filters that capture particles as small as 0.3 microns," say the HVAC experts from FinalFilters.com. "To put this in perspective, human hair measures about 50-100 microns in diameter; what's worse, the particles that cause hospital-acquired infections are roughly 150 times smaller than what you can see."

"Your filtration system must achieve efficiency ratings between 80% and 99.99% for these microscopic particles," they add, explaining that the specific rating depends on the area being served. Patient rooms may require 80% efficiency, while operating rooms demand 99.99% capture rates.

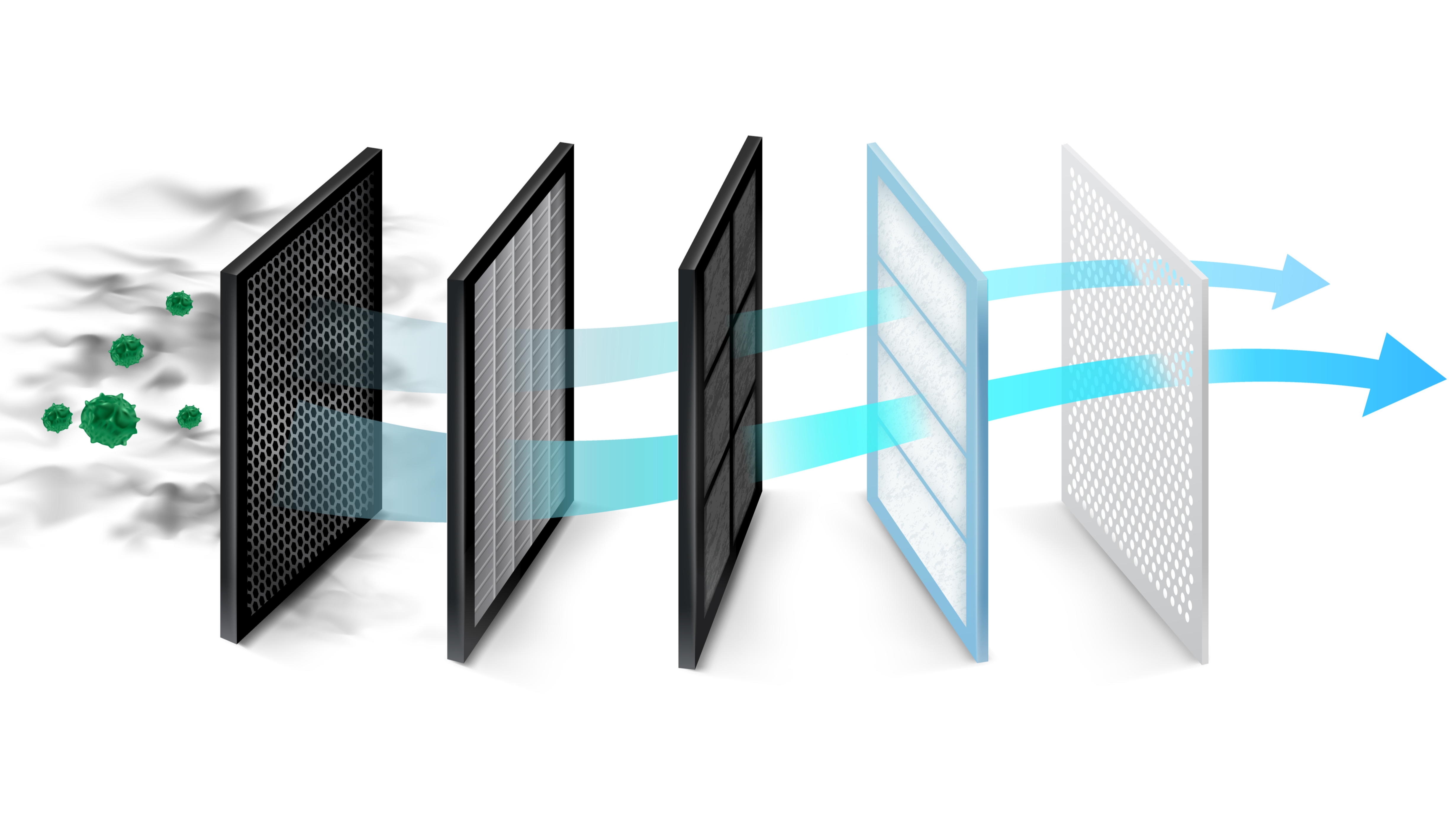

Medical-grade filters use tightly woven fibrous materials arranged in pleated configurations. This increases surface area without expanding the filter's footprint, allowing more particle capture within existing HVAC systems.

These filters often incorporate electrostatic charges that attract particles like microscopic magnets. The combination of physical barriers and electrostatic attraction ensures comprehensive particle removal from the air stream.

High-Efficiency Particulate Air (HEPA) filters represent the gold standard for medical facilities. They capture 99.97% of particles 0.3 microns or larger, making them ideal for operating rooms, isolation units, and other critical areas.

Standard pleated filters work well in less critical spaces like administrative offices and waiting areas. They cost less than HEPA filters but provide adequate protection for areas with minimal patient contact.

Some medical facilities benefit from carbon-enhanced filtration systems. These filters combine particle removal with gas-phase filtration, capturing odors, chemical vapors, and volatile organic compounds and they prove particularly valuable in areas where medical equipment releases chemical emissions or where odor control matters for patient comfort. The activated carbon's porous structure adsorbs gas molecules that standard filters cannot capture.

You cannot simply install medical-grade filters and forget about them. These high-performance filters require regular replacement to maintain effectiveness and a clogged filter doesn't just reduce air quality—it can damage your HVAC system and increase energy costs.

Most medical facilities follow quarterly replacement schedules for standard areas and monthly changes for critical spaces. However, your specific schedule depends on patient volume, local air quality, and system usage patterns.

Medical-grade filtration systems require professional installation and commissioning, improper installation can create air leaks that allow unfiltered air to bypass the filtration system entirely. Professional installers ensure proper seal installation, airflow balancing, and system integration. They also provide staff training on maintenance procedures and replacement schedules.

Medical-grade filters cost more than standard building filters, but this investment pays dividends in patient safety and regulatory compliance. Consider the cost of a single hospital-acquired infection lawsuit compared to annual filtration expenses and budget for both filter costs and installation expenses. While you might save money on cheaper filters initially, the hidden costs of poor air quality far exceed the savings.

High-quality filtration systems reduce cleaning requirements, extend HVAC equipment life, and create healthier environments for both patients and staff. These benefits translate to measurable cost savings over time and proper filtration also helps maintain accreditation status and avoid regulatory penalties. The Joint Commission and other accrediting bodies increasingly focus on environmental factors that affect patient outcomes.

Selecting appropriate filtration systems requires understanding the specific needs of each area within your facility. Operating rooms, patient rooms, isolation units, and administrative areas all have different requirements.

Filtration specialists help facilities balance performance requirements with budget constraints. They understand regulatory requirements and can recommend systems that meet compliance standards while controlling costs, they also stay up to date with changing regulations and emerging technologies that improve patient safety.

Professional suppliers also provide ongoing support, including maintenance scheduling, performance monitoring, and replacement planning. This support ensures your filtration system continues protecting patients long after installation.

Hospital filters require efficiency ratings between 80% and 99.99% for particles 0.3 microns or larger. Patient care areas typically need 80% efficiency, while operating rooms and isolation units require 99.99% efficiency ratings for maximum protection.

Most medical facilities replace filters quarterly in standard areas and monthly in critical spaces. However, replacement frequency depends on patient volume, local air conditions, and specific filtration system requirements, regular monitoring helps determine optimal replacement timing.

Standard building filters cannot provide adequate protection for medical facilities. Healthcare environments require specialized filters that capture microscopic pathogens and meet strict efficiency standards and using inappropriate filters puts patients at risk and violates healthcare regulations.

Medical facilities should work with who understand healthcare requirements and regulatory compliance standards. These professionals help select appropriate systems and provide ongoing maintenance support for optimal performance.